Exactly How Plastic Injection Molding Drives Performance in Automation

Exactly How Plastic Injection Molding Drives Performance in Automation

Blog Article

Secret Benefits of Utilizing Plastic Injection Molding in Manufacturing

Plastic injection molding has actually arised as a crucial technique in the production market, offering an array of advantages that dramatically enhance production processes. Remarkable advantages consist of exceptional production effectiveness, the capacity for elaborate layouts, and a favorable price framework that appeals to businesses of all sizes.

High Manufacturing Performance

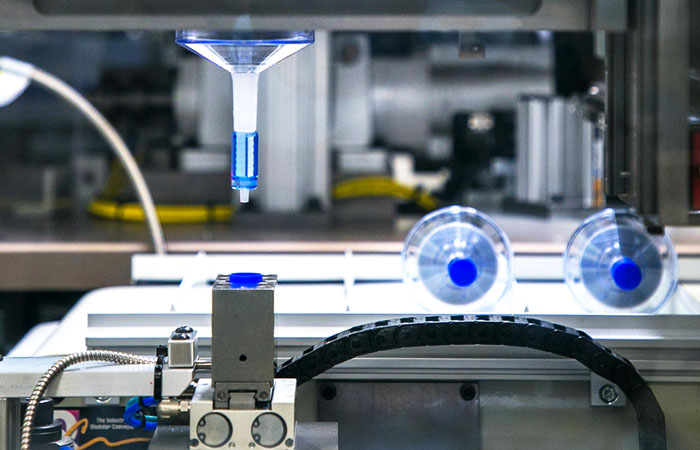

One of the most substantial benefits of plastic injection molding is its high production efficiency, which can lead to the fast production of hundreds of similar components within a short duration. This efficiency is greatly attributed to the automatic nature of the injection molding procedure. As soon as the preliminary configuration and mold creation are finished, the production of components can be scaled up dramatically without a matching rise in labor costs or time.

The procedure typically includes heating plastic pellets up until they thaw, infusing the molten material into an exactly created mold and mildew, and permitting it to cool down and solidify - Plastic Injection Molding. This cycle can be completed in plain secs to mins, depending on the complexity and size of the component being created. Therefore, producers can attain high result prices, making plastic shot molding an excellent selection for mass production

Moreover, the ability to produce big quantities regularly guarantees lower system expenses, making it an affordable option for services. This production efficiency not just satisfies market demands promptly however additionally improves the total competitiveness of manufacturers in various markets. As a result, plastic injection molding remains a favored approach for high-volume manufacturing applications.

Style Versatility

The capacities of plastic injection molding expand past high manufacturing effectiveness to encompass considerable style adaptability. This production procedure enables engineers and designers to produce complex and elaborate forms that might be challenging or difficult to achieve with other methods (Plastic Injection Molding). The capability to easily adapt and customize mold styles suggests that manufacturers can rapidly respond to transforming market demands and innovate new product styles without considerable retooling

In addition, plastic shot molding sustains a variety of products, including various thermoplastics and thermosetting polymers. This range allows the manufacturing of parts with unique residential properties, such as boosted strength, light-weight features, or specific thermal and electric features. Additionally, the process enables the combination of several functions into a single part, decreasing the need for assembly and minimizing possible factors of failing.

The accuracy of injection molding additionally makes certain that components are created with limited tolerances, improving fit and function. The versatility to generate little to big batches effectively better highlights its adaptability, making it a suitable choice for both prototyping and massive manufacturing. In general, style adaptability is a foundation benefit of plastic shot molding, driving innovation in various markets.

Cost-Effectiveness

Cost-effectiveness stands out as a significant advantage of plastic injection molding in production. This procedure permits the mass production of premium plastic elements at a reasonably affordable per device, specifically when contrasted to various other making methods. The efficiency of injection molding depends on its capability to create complicated shapes with very little waste, enhancing product use and minimizing total expenditures.

In addition, the rate of manufacturing is an essential consider cost-effectiveness. Once the first mold and mildew is developed, the moment needed to create each subsequent part is considerably decreased, resulting in enhanced output and faster turn-around times. This quick manufacturing ability not only meets high-volume needs yet likewise reduces labor costs, as automated systems can handle a lot of the procedure.

Additionally, the sturdiness and durability of injection-molded products add to their cost-effectiveness gradually. These elements frequently require much less maintenance and substitute, causing lower lifecycle costs for suppliers and end-users alike. In summary, the cost-effectiveness of plastic shot molding makes it an eye-catching alternative for services seeking to boost their manufacturing performance while preserving product top quality.

Material Versatility

Product flexibility is a characteristic of plastic injection molding, enabling makers to select from a vast range of polymers that fulfill certain performance demands. This flexibility enables for the manufacturing of elements customized to various applications, varying from automotive components to consumer products.

Generally used products include acrylonitrile butadiene styrene (ABDOMINAL), polycarbonate (COMPUTER), and polypropylene (PP), each offering distinct buildings such as effect resistance, heat resistance, and chemical security. Producers can select products based on qualities like toughness, weight, and thermal stability, making sure completion product satisfies aesthetic and practical demands.

Moreover, the capability to integrate various polymers through co-injection techniques additional boosts product versatility. This permits the development of multi-layered parts with distinctive qualities, such as soft-touch surfaces integrated with inflexible architectural components.

Additionally, developments in naturally degradable and recycled products are increasing the alternatives available, lining up with sustainability objectives in production. On the whole, the diverse product choices in plastic injection molding empower manufacturers to innovate and optimize their items, promoting the growth of very specialized and competitively useful remedies.

Boosted Item Durability

Enhanced item longevity is just one of the substantial benefits used by plastic shot molding, as the manufacturing process permits precise control over product properties and part style. Home Page This precision guarantees that the end products show improved mechanical strength and resilience, which are essential variables in an array of applications, from consumer goods to commercial elements.

Moreover, the elaborate geometries possible through shot molding enable the creation of elements that can stand up to stress and strain much better than standard production approaches. The consistent wall thickness and reduced find out material waste likewise add to the general stability of the item, decreasing the opportunities of failing throughout its lifecycle.

Final Thought

In final thought, plastic injection molding offers significant benefits in manufacturing, consisting of high production efficiency, layout versatility, and cost-effectiveness. The method's capacity to quickly produce huge quantities of identical components while reducing labor and product waste is vital. Additionally, the versatility in product selection adds to enhanced item sturdiness and reduced lifecycle expenses. These elements jointly establish plastic shot molding as an optimal option for mass manufacturing applications, attending to the vibrant needs of modern-day production atmospheres.

Plastic injection molding has emerged as a crucial technique in the manufacturing market, supplying a range of advantages that substantially improve production processes.One of the most considerable benefits of plastic shot molding is its high manufacturing performance, which can result in the rapid manufacturing of thousands of identical parts within a short timeframe. Plastic Injection Molding.The abilities of plastic shot molding expand past high manufacturing performance to incorporate significant design flexibility.In conclusion, plastic injection molding presents significant advantages in manufacturing, including high production efficiency, design adaptability, and cost-effectiveness. These factors collectively go develop plastic shot molding as an optimum remedy for mass manufacturing applications, resolving the vibrant requirements of contemporary manufacturing atmospheres

Report this page